Induction Brazing Market Size, Share & Industry Analysis, By Type (Manual Brazing Machines and Automatic Brazing Machines), By End-User (Automotive, Aerospace, Medical, HVAC, Electrical, and Others), and Regional Forecast, 2026-2034

Induction Brazing Market Size

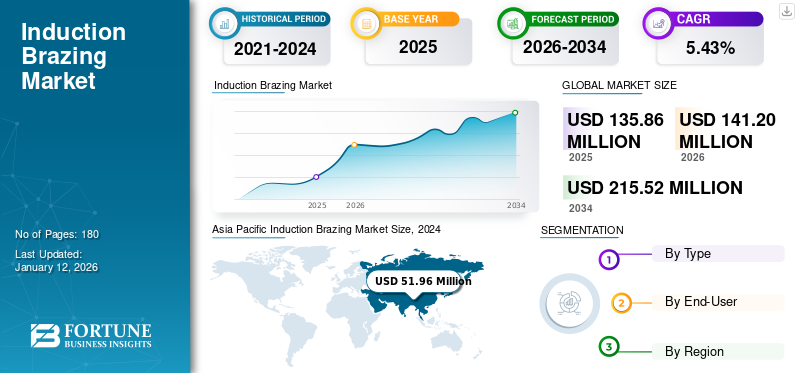

The global induction brazing market size was valued at USD 135.86 million in 2025 and is projected to grow from USD 141.2 million in 2026 and reach USD 215.52 million by 2034, exhibiting a CAGR of 5.43% during the forecast period. Asia Pacific dominated global market with a share of 39.85% 2025. The Induction brazing market in the U.S. is projected to grow significantly, reaching an estimated value of USD 40.44 million by 2032.

Induction brazing is a metal joining process that uses electromagnetic induction to heat metals to the melting point of a filler material while keeping the base metals below their melting points. It allows precise control over temperature and heating duration, leading to consistent and high-quality joints. Automation can be integrated into the process for mass production, ensuring uniformity and efficiency. It is applicable in various industries, such as automotive, aerospace, electronics, and manufacturing for joining components, such as pipes, fittings, electrical connectors, heat exchangers, and more.

Various nations across the globe faced unmatched challenges posed by the COVID-19 pandemic, with people suffering from health and financial conditions. Many industries, such as automotive, aerospace, construction, and manufacturing experienced slowdowns or temporary shutdowns due to pandemic-related restrictions, which further led to decreased demand for induction brazing equipment and services. According to the Royal Institution of Chartered Surveyors, around 25% of the projects were halted in the second quarter, and on-site productivity fell by 12% in 2020. Additionally, the International Organization of Motor Vehicle Manufacturers reported that automotive production in 2020 declined by around 16% to less than 78 million vehicles compared to 2019. The shutdown of a large part of the auto industry and its many suppliers across the globe for several weeks resulted in a decline in the demand for induction brazing services.

Induction Brazing Market Trends

Development of Advanced Coil Designs to Positively Impact Market Growth

The induction coil is an important component in the process as it is responsible for generating the electromagnetic fields necessary for heating the work piece. Innovations in the coil design have played a pivotal role in enhancing the efficiency, versatility, and adaptability of induction brazing systems. Manufacturers are increasingly focusing on developing more advanced and flexible coil designs that accommodate a diverse range of workpiece geometries. This adaptability is crucial in industries where components vary significantly in size, shape, and material composition. These coil design innovations can significantly boost the ability of its brazing machines to handle intricate workpiece configurations.

Advancements in coil design have contributed to improved heat distribution and precision during the brazing process. The ability to achieve precise and localized heating is critical for ensuring the integrity of the joint while minimizing heat-affected zones in the surrounding areas. This precision is particularly useful in aerospace and automotive industries, where stringent quality standards must be met. Another aspect of innovation in coil design involves the development of modular and interchangeable coils. This allows for adjustments to accommodate different production requirements. Manufacturers can now switch between various coil configurations without extensive retooling, enabling a more agile and efficient production process.

Download Free sample to learn more about this report.

Induction Brazing Market Growth Factors

Rising Production of Automobiles to Surge Demand for Induction Brazing Services

The rising production of automobiles, accompanied by their soaring sales, serves as a significant driver for the global induction brazing market growth. The expansion of the global economy, coupled with surging population, income, urbanization, and industrialization, is fueling the demand for automobiles, further boosting their production. According to the International Organization of Motor Vehicle Manufacturers, the total production of motor vehicles worldwide surged by around 6% to more than 85 million vehicles in 2022 as compared to 2021. The heightened production of motor vehicles was accompanied by surging sales, which grew from around 78.7 million in 2020 to nearly 81.6 million in 2022.

As the automotive industry experiences continuous growth, induction brazing technology plays a crucial role in process manufacturing. It is widely employed in the production of automotive components, such as exhaust systems, transmission assemblies, and engine parts. The demand for high-quality and reliable components has intensified with the increasing complexity of modern vehicle designs. It offers advantages, such as precise temperature control, localized heating, and improved energy efficiency, making it well-suited for automotive applications. The trend toward lightweight materials and the need for durable, high-performing joints in critical automotive components will further propel the adoption of induction brazing. As automotive production scales up globally, the market is poised to benefit from the industry's constant reliance on advanced and efficient joining technologies.

Expansion of Construction Industry to Lead Market Growth

The construction sector's expansion plays a crucial role in driving market growth. Rise in construction activities, including the development of residential, commercial, industrial, and public infrastructures, is fueled by urbanization, population growth, and increasing affluence. In addition, governments’ investments in public infrastructure projects, such as transportation, utilities, and smart cities, coupled with rising housing initiatives, have accelerated construction activities worldwide. For instance, Saudi Arabia announced a pipeline of infrastructure projects worth USD 1 trillion, including Neom, Riyadh Metro, and many others to diversify its economy beyond oil by 2030. Thus, induction brazing technology becomes instrumental in the fabrication and assembly of various components used in construction equipment, infrastructure, and architectural structures. It offers precise and localized heating, making it ideal for joining materials in construction applications where accuracy and efficiency are paramount.

Moreover, the industry's demand for reliable and high-quality brazing solutions for components, such as HVAC systems, pipelines, and structural elements will further propel the adoption of induction brazing. Additionally, the construction sector's increasing emphasis on energy efficiency and sustainability aligns with the benefits offered by induction brazing, which is known for its efficiency and reduced environmental impact. As construction projects expand globally, the market stands to benefit from the industry's ongoing need for advanced and efficient joining technologies to manufacture construction-related components.

RESTRAINING FACTORS

Prevalence of Alternative Technologies to Limit Induction Brazing Market Growth

Alternative joining technologies, such as traditional brazing methods, welding, and adhesive bonding, which may incur lower upfront costs or are deeply entrenched in certain industries, pose strong competition to market growth. While this type of brazing offers advantages, such as precise heating and energy efficiency, industries accustomed to existing technologies may be hesitant to invest in and transition to a relatively newer method. The familiarity and established track record of alternative technologies and potential resistance to change can impede the widespread adoption of market. Overcoming this restraint involves highlighting the unique benefits of this form of brazing, emphasizing its efficiency, precision, and environmental advantages, and demonstrating its superiority in specific applications to shift industry perceptions and encourage adoption.

Induction Brazing Market Segmentation Analysis

By Type Analysis

Automatic Brazing Machines Hold Largest Market Share Due to Improved Efficiency

Based on type, the market is segmented into manual brazing machines and automatic brazing machines.

The automatic induction brazing machine segment dominates the market with a share of 69.23% in 2026. This machine is equipped with automated unloading and loading mechanisms, part positioning systems, and process control parameters. It can run continuously with minimal human intervention and is generally merged into production lines for high-volume production. This segment is estimated to grow at a significant rate owing to the machine’s high level of automation that contributes to improved efficiency and consistency in the brazing process.

Manual brazing machines are also one of the major segments due to their high degree of flexibility and adaptability. Operators can control and adjust various parameters based on the specific requirements of each brazing operation.

By End-User Analysis

To know how our report can help streamline your business, Speak to Analyst

Automotive Segment Dominates Market Due to High Requirement in Different Applications

Based on end-user, the market is segmented into automotive, aerospace, medical, HVAC, electrical, and others. The automotive segment holds a major share of the market contributing 35.52% globally in 2026 and owing to the high requirement for induction brazing for various applications, including the joining of components, such as transmission components, exhaust systems, fuel systems, and heat exchangers. Moreover, the rising sales of automobiles, such as passenger cars, medium & high commercial vehicles, and others due to rising disposable income and expansion of the economy have also resulted in the high production of automobiles, further increasing the demand.

The aerospace segment is also witnessing steady growth in the market due to the rising number of air passengers across the globe, further leading to the requirement for aircraft. Moreover, increasing investments in the defense sector by governments across the globe for expanding their military power has resulted in the growth of the fleet size of military aircrafts. It is also required for the assembly of components, such as aircraft engine parts, heat exchangers, fuel systems, and hydraulic components.

Furthermore, the HVAC segment is projected to grow at a notable rate in the market due to the rising construction activities worldwide. The growing initiatives toward accelerating the growth of the tourism industry has led to the construction of airports, hotels, and public infrastructures. The installation of HVAC systems in these infrastructures has been an important component that further necessitates the demand.

REGIONAL INSIGHTS

Geographically, the market is studied across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Asia Pacific Induction Brazing Market Size, 2024

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific

Asia Pacific dominated the market with a valuation of USD 54.15 billion in 2025 and USD 56.59 billion in 2026. Asia Pacific accounts for a majority of the global induction brazing market share owing to the surging construction activities, increasing automotive production, and the presence of a huge electronics industry. The increasing population in India, China, Indonesia, and others is pushing the construction of affordable housing and commercial & industrial spaces. For instance, in August 2023, the Chinese government approved guidelines for planning and constructing affordable housing in the country to address the housing shortage problem. This is further supported by China's central bank's relaxation of residential housing loan rules for boosting loan applications and house purchases in the country. The Japan market is valued at USD 6.76 billion by 2026, the China market is valued at USD 34.34 billion by 2026, and the India market is valued at USD 5.47 billion by 2026.

North America and Europe

North America and Europe will also hold a considerable share of the market as these regions consist of huge commercial and industrial spaces. The rising manufacturing of automobiles, including electric vehicles is projected to fuel the demand for market in these regions. Electric vehicle production is also supported by various government initiatives and tax reduction programs to achieve the global net zero target for carbon emissions by 2050. For instance, the U.S. government launched the 2022 Climate Act to support the production and sales of electric vehicles and their components in the country. Under this initiative, companies are eligible for substantial tax credits when they invest in electric vehicle production and related components. Additionally, consumers can receive up to USD 7,500 in incentives for purchasing an electric vehicle. The U.S. market is valued at USD 30.16 million by 2026 and The UK market is valued at USD 1.79 billion by 2026, while the Germany market is valued at USD 8.3 billion by 2026.

Middle East & Africa and Latin America

The Middle East & Africa and Latin America are projected to witness steady growth in the market due to the rising greenfield investments in Mexico, Brazil, GCC, and other countries. The visionary targets of the GCC countries to expand the manufacturing and tourism industries will support the construction of commercial & industrial spaces and public infrastructures. This will further provide a positive market outlook.

Key Industry Players

Ajax Tocco Dominates Market Due to its Expertise in Induction Heating and Brazing Sector

Ajax TOCCO offers traditional and custom equipment. From inline, stand-alone, indexing, to continuous, its team of process and application engineers has the potential and expertise to give the best system to meet production requirements. It provides manual load, automation, multi-station, tabletop systems, and fluxless brazing.

LIST OF TOP INDUCTION BRAZING COMPANIES:

- Inductotherm Group (U.S.)

- UltraFlex (U.S.)

- Ajax Tocco Magnethermic Corporation (U.S.)

- VBC Group (U.K.)

- ENRX Group (Norway)

- MSI Automation (U.S.)

- Magneforce, Inc. (U.S.)

- eldec Induction GmbH (Germany)

- Esaris Industries (France)

- SAET EMMEDI (Italy)

KEY INDUSTRY DEVELOPMENTS:

- December 2023 – inTEST Corporation, a global provider of advanced test and process technology solutions used in manufacturing & testing across key markets, such as automotive/EV, defense/aerospace, industrial, life sciences, security, and semiconductor, introduced the latest EKOHEAT 2 induction heating products through its subsidiary Ambrell. The EKOHEAT 2 represents the next evolutionary step in Ambrell's VPA technology, showcasing cutting-edge advancements in the field.

- March 2023 – Industrial induction heating company EFD Induction and inductive charging and power supply innovator IPT Technology launched ENRX. Operating under its new name, ENRX will offer induction technology solutions for inductive heating, charging, and power supply, all designed with a low or negligible carbon footprint.

- May 2022 – ESF Elbe-Stahlwerke Feralpi, a German steel producer, selected Danieli Technologies for its upcoming long-product rolling mill in Riesa, northeastern Germany. The new mill will be seamlessly connected to the existing conticaster through a 300-meter hot-charge roller table, eliminating the need for a conventional gas-heating furnace. This setup will exclusively rely on the induction heating technology, resulting in zero CO2 emissions. Additionally, a state-of-the-art in-line billet welder will be incorporated to facilitate continuous rolling without interruptions.

- April 2022 – Schaeffler announced the expansion of its portfolio of energy-efficient induction heaters. Schaeffler unveiled a new series of mounting tools under the name HEATER, designed to provide even, controlled, and gentle heating of workpieces. This marks the company’s inaugural induction heating-based mounting product following the acquisition of BEGA International B.V., a specialized tool manufacturer.

- July 2021 – ABB accomplished the commissioning of the Induction xP Plus profiler system on PM3 at Bilt Graphic Paper Products Limited (BGPPL) in Ballarpur, India, with remote assistance from China. ABB's latest Induction xP Plus stood out as the premier Cross-Direction (CD) caliper profile control, aiming to achieve optimal induction heating in the shortest duration. This is intended to minimize product variability and facilitate swift adjustments to sheet finishing profiles.

REPORT COVERAGE

The report provides a detailed analysis of the market and focuses on key aspects such as leading companies, product/service types, and leading end-users of the product. Besides, it offers insights into the market trends and highlights key industry developments. In addition to the factors mentioned above, the report encompasses several factors that contributed to the growth of the market in recent years.

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 5.43% from 2026 to 2034 |

|

Unit |

Value (USD Million) |

|

Segmentation |

By Type, End-user, and Region |

|

Segmentation |

By Type

|

|

By End-User

|

|

|

By Region

|

Frequently Asked Questions

A study by Fortune Business Insights states that the global market was valued at USD 135.86 million in 2025.

The global market is projected to record a CAGR of 5.43% over the forecast period.

The Asia Pacific market size was valued at USD 54.15 million in 2025.

Based on end-user, the automotive segment holds a dominating share of the global market.

The global market size is expected to reach a valuation of USD 215.52 million by 2034.

Rise in the production of automobiles will surge the demand for induction brazing services.

Inductotherm Group, UltraFlex, Ajax Tocco Magnethermic Corporation, ENRX Group, MSI Automation, and others are some of the top players actively operating across the market.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us