Piezoelectric Devices Market Size, Share & Industry Analysis, By Type (Disc, Plate, and Ring), By Application (Sensors, Transducers, Motors, Actuators, and Others), By Industry (Automotive, Healthcare, Aerospace & Defense, Consumer Electronics, Manufacturing, and Others), and Regional Forecast, 2026-2034

KEY MARKET INSIGHTS

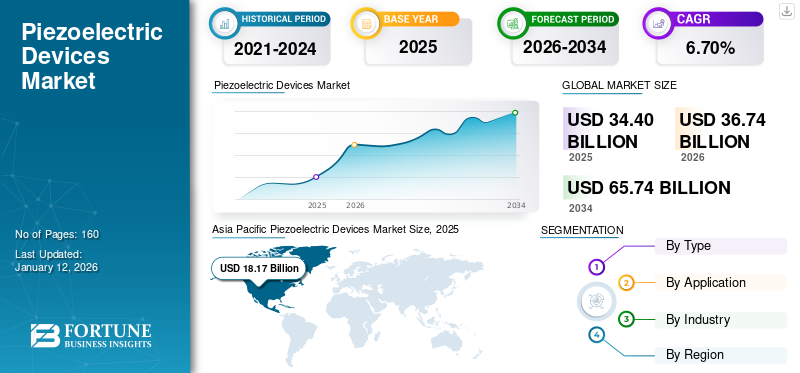

The global piezoelectric devices market size was valued at USD 34.4 billion in 2025. The market is projected to grow from USD 36.74 billion in 2026 to USD 65.74 billion by 2034, exhibiting a CAGR of 6.70% during the forecast period. Asia Pacific dominated the global market with a share of 52.80% in 2025.

Piezoelectric instruments utilize the piezoelectric effect to convert mechanical vibrations or deformations into electrical signals or vice versa. This phenomenon occurs in certain materials, such as quartz crystals or specialized ceramics, where an applied mechanical force generates an electrical charge or an applied voltage induces mechanical deformation. The piezoelectric instrument industry is experiencing significant growth due to its diverse applications in various sectors. In healthcare, piezoelectric sensors are used in ultrasound imaging for precise diagnostics. In industrial automation, they enable precise motion control in robotics and actuators. In addition, piezoelectric devices are vital in the aerospace and automotive industries for sensor and energy harvesting applications.

Moreover, the demand for clean and renewable energy sources has boosted industry growth. Energy harvesting from ambient vibrations and movements using piezoelectric materials is being explored for powering sensors and low-power electronics. As technology advances and new applications emerge, the piezoelectric instrument industry is poised for continuous expansion and innovation.

COVID-19 IMPACT

Increasing Piezoelectric Component Demand in Healthcare Devices during Pandemic Boosted Market Growth

The COVID-19 pandemic had a dual impact on the piezoelectric instrument market. The disruptions in global supply chains caused significant delays in manufacturing and distributing piezoelectric components, impacting the availability of crucial piezoelectric components. Economic uncertainties stemming from the pandemic led to reduced budgets for research and development, potentially slowing down innovation in piezoelectric applications. Many companies also redirected their resources toward the production of essential pandemic-related equipment, diverting attention away from piezoelectric products. Furthermore, the postponement or cancellation of non-urgent industry goods and elective surgeries reduced the immediate demand for piezoelectric devices in such applications.

However, the urgency of the pandemic accelerated the adoption of piezoelectric instruments in critical healthcare areas, such as ventilators, respiratory monitoring, and point-of-care testing. Increased investments and innovations in piezoelectric technologies emerged within the healthcare sector, leading to the development of novel and enhanced medical devices. The rise of telemedicine and remote patient monitoring during the pandemic bolstered the demand for piezoelectric sensors in remote healthcare devices such as wearable health trackers. In addition, the pandemic underscored the importance of resilient medical supply chains and advanced healthcare technologies, potentially paving the way for long-term growth and investment in the piezoelectric instrument market.

Piezoelectric Devices Market Trends

Increasing Trend of High Machine Efficiency and Employee Safety to Propel Market Growth Globally

The growing inclination to enhance machine efficiency and ensure worker safety has driven the market growth. Industries such as construction, manufacturing, agriculture, and mining increasingly recognize the potential of advanced control systems to address these critical needs. Efficiency gains are paramount as industries strive for cost savings and optimal resource utilization. These devices enable machines to operate with heightened accuracy and productivity through real-time monitoring, precision guidance, and automation. Concurrently, the focus on worker safety has intensified, especially with evolving labor regulations and increased awareness of occupational hazards. The devices play a pivotal role here by enabling remote operation and reducing the need for direct human involvement in hazardous tasks. Autonomous machinery and sensor-based technologies can prevent accidents and injuries, safeguarding workers' well-being. Integrating piezoelectric devices addresses increased efficiency and team member safety. Improved efficiency translates to higher productivity and reduced manual labor, lowering workers' risk exposure. Furthermore, advanced technologies such as collision avoidance and proximity sensors enhance worksite safety, driving market growth.

Download Free sample to learn more about this report.

Piezoelectric Devices Market Growth Factors

Heavy Adoption of Piezoelectric Components in Aerospace & Defense Industry to Drive Market Growth

The aerospace and defense industry is heavily adopting the piezoelectric components, which is significantly responsible for driving the growth of the piezoelectric instruments market. This is primarily due to the unique properties and capabilities of piezoelectric materials, which make them valuable in this sector. In aerospace, piezoelectric sensors and actuators are used for a range of critical applications. Piezoelectric sensors provide precise measurements of various parameters such as pressure, vibration, and temperature, ensuring the safety and performance of aircraft. They are also utilized in structural health monitoring systems to detect potential structural flaws, improving maintenance efficiency and safety.

In defense applications, piezoelectric devices play a crucial role in acoustic and sonar systems, where their sensitivity to pressure changes allows for the accurate detection of underwater threats. In addition, they are integrated into smart ammunition and guidance systems, enhancing their accuracy and reliability. The demand for lightweight, compact, and high-performance solutions in aerospace and defense aligns perfectly with piezoelectric technology, making it an integral part of these industries and propelling the growth of the piezoelectric instruments market. As these sectors continue to advance and modernize, the adoption of piezoelectric components is expected to record further growth.

RESTRAINING FACTORS

Lack of Skilled Labor and Development of Alternative Materials May Hinder Market Growth

The piezoelectric device industry faces challenges that could hinder its growth, with two significant factors being the lack of skilled labor and the development of alternative materials such as potassium sodium bismuth titanate (KSBT). Primarily, the shortage of skilled labor in the field of piezoelectric technology may impede piezoelectric devices market share. As the demand for these devices is increasing across various sectors, there's a need for engineers, researchers, and technicians with specialized knowledge in materials science and electronics. The scarcity of such skilled professionals can lead to delays in research, development, and manufacturing processes. Moreover, the emergence of alternative materials, such as potassium sodium bismuth titanate (KSBT), poses a threat to traditional piezoelectric materials. These new materials may offer improved performance characteristics, such as higher piezoelectric coefficients or better temperature stability. If these alternatives become more cost-effective and readily available, they could divert investment away from traditional piezoelectric materials, impacting the growth of existing industry players. Addressing these challenges requires a concerted effort from the piezoelectric industry to invest in workforce development and adapt to evolving material technologies to ensure continued growth and competitiveness in the market.

Piezoelectric Devices Market Segmentation Analysis

By Type Analysis

Ring Segment Held Prominent Market Share Owing to Increasing Use in Healthcare Equipment

Based on type, the market is classified into disc, plate, and ring.

In 2026, the piezoelectric ring segment dominated the market with a share of 41.69%, due to its extensive use in the healthcare sector. These rings are integral components in advanced medical devices such as ultrasound transducers, ensuring high-quality imaging and diagnostic capabilities. The growing demand for medical equipment has propelled the piezoelectric ring market expansion.

In addition, discs and plates are adopted in applications such as medical sensors, non-invasive monitoring, and portable diagnostic devices aiding in market growth. Their versatility and precision make them indispensable in healthcare, contributing to the overall rise in demand for these devices across various sectors.

By Application Analysis

Sensors Segment Held the Highest Market Revenue Owing to the Increasing Need for Optimization of Smart Sensing Device

Based on application, the market is classified into sensors, transducers, motors, actuators, and others (energy generators & others).

In 2026, the piezoelectric sensors segment held a dominating share of 28.33% the market due to the increasing demand for miniaturization and optimization in smart sensing devices. These sensors offer compact and highly responsive solutions for various applications, including Internet of Things (IoT) devices and wearables.

The motor segment is projected to experience the highest CAGR over the forecast period, driving the demand for piezoelectric transducers. These transducers are essential in precision control systems, robotics, and automotive applications, aligning with the trend toward efficient and compact actuators. As a result, piezoelectric actuators are also experiencing growth, ensuring precise movement and positioning in various industries, from manufacturing to aerospace.

By Industry Analysis

To know how our report can help streamline your business, Speak to Analyst

Manufacturing Segment Leads the Market with Production Efficiency and Quality

By industry, the market is segmented into automotive, healthcare, aerospace & defense, consumer electronics, manufacturing, others (IT & telecom and others).

In 2026, the manufacturing segment held a dominating market share of 30.06%, This was due to the pivotal role of piezoelectric devices in quality control and automation. These instruments enable precise measurements, contributing to manufacturing efficiency and product quality.

The consumer electronics segment is set to exhibit the highest CAGR over the forecast period, driving increased integration of piezoelectric components in devices such as smartphones and wearables. The trend extends to aerospace and defense, where piezoelectric sensors and actuators enhance navigation and stability.

Similarly, the automotive industry benefits from these devices for vehicle safety and emissions control. Additionally, healthcare applications continue to grow, with piezoelectric sensors and transducers supporting medical diagnostics and imaging.

REGIONAL INSIGHTS

Based on region, the market is segmented into North America, Europe, Asia Pacific, South America, and the Middle East & Africa.

Asia Pacific Piezoelectric Devices Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific dominated the market with a valuation of USD 18.17 billion in 2025 and USD 19.62 billion in 2026. The piezoelectric device industry is catalyzing substantial growth in the Asia Pacific region, particularly in China, Taiwan, South Korea, and Japan. China, with its robust manufacturing sector and burgeoning tech industry, is driving the demand for piezoelectric sensors and actuators in applications ranging from consumer electronics to automotive systems. The Japan market is valued at USD 4.05 billion by 2026, the China market is valued at USD 8.71 billion by 2026, and the India market is valued at USD 2.09 billion by 2026. Taiwan is emerging as a hub for semiconductor production, relying heavily on piezoelectric components for precision manufacturing. South Korea's leadership in electronics and robotics fuels the adoption of automation and medical devices. Meanwhile, Japan's dedication to innovation utilizes piezoelectric technology in cutting-edge fields such as healthcare and aerospace. Together, these nations are driving the piezoelectric industry's expansion across the region.

To know how our report can help streamline your business, Speak to Analyst

Piezoelectric devices are gaining popularity in India, Singapore, Malaysia, Indonesia, and Australia due to significant technological advancements in Asia Pacific. These countries are increasingly utilizing piezoelectric components in sectors such as healthcare, automotive, and energy harvesting. Their sensitivity, reliability, and energy efficiency make them ideal for diverse applications, fostering innovation and sustainable solutions across the region. As a result, this market is flourishing, driven by the ongoing technological evolution in the Asia Pacific nations.

The piezoelectric component industry in North America is witnessing steady growth, driven by advancements in healthcare technology, automotive applications, and industrial automation. In the U.S., there is a rising demand for piezoelectric sensors in medical devices, such as ultrasound machines and wearable health monitors. In Canada, the automotive sector is embracing piezoelectric actuators for fuel efficiency and emissions control. With the continued focus on innovation and research, North America remains a key player in the global piezoelectric market. The U.S. market is valued at USD 7.11 billion by 2026.

Europe is experiencing robust growth owing to its thriving automotive, aerospace, and industrial sectors. Germany and France are leading the way in implementing piezoelectric technology for precise control and automation in manufacturing processes. In the automotive realm, piezoelectric sensors are integral to fuel injection systems and exhaust control. Moreover, the aerospace industry relies on piezoelectric materials for vibration control and sensing. Europe's commitment to sustainability also drives the adoption of piezoelectric energy harvesting solutions. The strong research and development initiatives in the region ensure its continued prominence in the global piezoelectric market. The UK market is valued at USD 1.08 billion by 2026, while the Germany market is valued at USD 1.47 billion by 2026.

The Middle East & Africa is steadily expanding, driven by the region's growing focus on infrastructure development and renewable energy. In the Middle East & Africa, South Africa, UAE, and Saudi Arabia are incorporating piezoelectric sensors into construction projects to monitor structural integrity.

South America, Brazil, Argentina, and Mexico are embracing piezoelectric sensors and actuators for vehicle emissions control and engine management systems. In addition, in the renewable energy sector, Chile is exploring piezoelectric energy harvesting solutions for environmental monitoring in remote areas. South America's interest in sustainability and manufacturing efficiency positions it as an emerging market with significant growth potential in the global piezoelectric industry.

Key Industry Players

Murata Industry Leads Owing to its Investment in Research & Development of New Product

Prominent companies such as Murata hold the largest market share globally, primarily due to their substantial investments in research and development, leading to the introduction of new products. In addition, companies such as Piezo System Jena, Morgan Advanced Materials, Mad City Labs, Inc., Poliak A/S, CTS Corporation, Piezomechanik Dr. Lutz Pickelmann GmbH, Physik Instrumente, CeramTec, and APC International, Ltd., are expanding their global presence by launching innovative products and forming partnerships and collaborations. Moreover, the market is experiencing growth from the entry of numerous small and medium-sized enterprises, contributing to its overall expansion.

List of Top Piezoelectric Devices Companies

- Piezo System Jena (Germany)

- Murata (Japan)

- Morgan Advanced Materials (U.K.)

- Mad City Labs, Inc. (U.S.)

- Poliak A/S (Denmark)

- CTS Corporation (U.S.)

- Piezomechanik Dr. Lutz Pickelmann GmbH (Germany)

- Physik Instrumente (Germany)

- CeramTec (Germany)

- APC International, Ltd. (U.S.)

KEY INDUSTRY DEVELOPMENTS

- April 2023: A research group at KAIST, under the leadership of Professor Keon Jae Lee from the Department of Materials Science and Engineering, in collaboration with the College of Medicine at the Catholic University of Korea, successfully created an exceptionally sensitive wearable blood pressure sensor based on piezoelectric technology.

- June 2022: CTS Corporation, a renowned global semiconductor manufacturer, completed the acquisition of Ferroperm Piezoceramics, a leading supplier of piezoelectric devices for healthcare, from Meggitt PLC for a total transaction value of USD 72.2 million.

- February 2022: CTS Corporation successfully concluded the purchase of TEWA Temperature Sensors SP and its affiliated companies at a total value of USD 24.5 million. TEWA is a well-established creator and producer of top-tier temperature sensors known for its exceptional ceramic technology that provides exceptional stability and reliability. This technological advantage has significantly propelled TEWA's expansion in the industry.

- September 2020: STMicroelectronics, a prominent semiconductor industry leader with a comprehensive presence in various electronics applications and a distinguished position as a global pioneer in Micro-Electromechanical Systems (MEMS) technology, unveiled a partnership with A-STAR’s IME, a distinguished research institute located in Singapore, and ULVAC, a top-tier Japanese manufacturing-tool provider. Their collective endeavor aimed to establish and oversee an 8-inch (200mm) research and development line that would concentrate on Piezo MEMS technology. This facility would be integrated within ST's existing manufacturing facility situated in Singapore.

- January 2019: Aerotech, Inc. and Micronix USA announced a strategic alliance aimed at providing complementary precision motion solutions to both the industrial and research sectors. This collaborative effort would enhance the capabilities of each organization, paving the way for broader industry applications that demand robust and user-friendly Nano positioning solutions. In unison, they would offer an extended array of stages, controllers, drives, and software, catering to the needs of cutting-edge applications requiring precise positioning.

REPORT COVERAGE

The report provides a detailed analysis of the global market and focuses on key aspects such as leading companies, product/service types, and leading industry applications of the product. Besides this, the report offers insights into the market trends and highlights the key industry developments. In addition to the abovementioned factors, the report encompasses several factors that have contributed to the growth in recent years.

Request for Customization to gain extensive market insights.

Report Scope and Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Estimated Year |

2026 |

|

Forecast Period |

2026-2032 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 6.70% from 2026 to 2034 |

|

Unit |

Value (USD Billion) |

|

Segmentation |

By Type

By Application

By Industry

By Region

|

Frequently Asked Questions

Fortune Business Insights says the market stood at USD 34.4billion in 2025.

In 2034, the global market is expected to be valued at USD 65.74 billion.

The market is set to exhibit a CAGR of 6.70% during the forecast period (2026-2034).

Asia Pacific is anticipated to be the dominant region and was valued at USD 18.17 billion in 2025.

By industry, the consumer electronics segment is expected to witness the highest CAGR during the forecast period.

The increasing trend of high machine efficiency and employee safety is set to propel market growth globally.

The heavy adoption of piezoelectric devices in aerospace & defense industry is a key factor driving market growth.

Piezo System Jena, Morgan Advanced Materials, Mad City Labs, Inc., Poliak A/S, CTS Corporation, Piezomechanik Dr. Lutz Pickelmann GmbH, Physik Instrument, CeramTec, and APC International, Ltd., and others are the top players in the market.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us