UV Stabilizers Market Size, Share & Industry Analysis, By Type (Hindered Amine Light Stabilizers (HALS), UV Absorbers, Quenchers, and Others), By End-Use Industry (Packaging, Automotive, Agriculture, Building & Construction, Adhesives & Sealants, and Others), and Regional Forecast, 2026-2034

KEY MARKET INSIGHTS

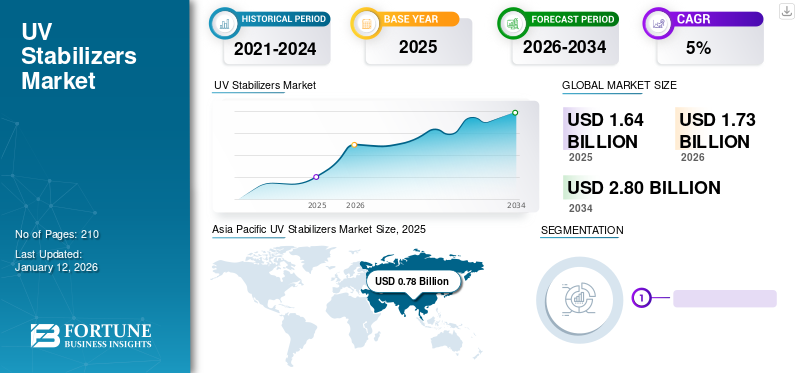

The global UV stabilizers market size was valued at USD 1.64 billion in 2025 and is projected to grow from USD 1.73 billion in 2026 to USD 2.8 billion by 2034 at a CAGR of 5.50% during the 2026-2034 forecast period. Asia Pacific dominated the uv stabilizers market with a market share of 48% in 2025. Moreover, the UV stabilizers market size in the U.S. is projected to grow significantly, reaching an estimated value of USD 359.34 million by 2032, driven by growing awareness among consumers and manufacturers about the harmful effects of UV radiation.

UV stabilizers are a highly effective means of safeguarding materials against the damaging effects of UV radiation. They absorb UV light and then convert it into heat, which is dispersed harmlessly. These stabilizers are widely used in a variety of applications, including plastics, coatings, and textiles. They are particularly essential for outdoor use, where exposure to sunlight can lead to material degradation over time. Each type holds unique properties and advantages. Among the most commonly used varieties are benzophenones, benzotriazoles, hindered amine light stabilizers, and others, which are expected to foster the UV stabilizers market growth.

The outbreak of COVID-19 had a profound and far-reaching impact on the market, causing major disruptions to the global supply chain and significantly reducing the demand for UV stabilizers. As a result, product manufacturers faced severe logistics & transportation challenges as they attempted to navigate their products to meet a wide range of demands. Despite these challenges, the industry demonstrated resilience and adaptability, with many companies innovating to drive the obstructed demand across the market. Manufacturers focused on pushing their limits to mitigate these negative effects and identify new growth opportunities.

Global UV Stabilizers Market Key Takeaways

Market Size & Forecast:

- 2025 Market Size: USD 1.64 billion

- 2026 Market Size: USD 1.73 billion

- 2034 Forecast Market Size: USD 2.8 billion

- CAGR: 5.50% from 2026–2034

Market Share:

- Asia Pacific dominated the UV stabilizers market with a 48% share in 2025, driven by widespread product usage in the industrial and commercial sectors, and strong demand from packaging, automotive, and construction industries across China, India, and Japan.

- By type, Hindered Amine Light Stabilizers (HALS) are expected to retain the largest market share in 2025, supported by their higher UV stabilization efficiency, low toxicity, and extensive application in automotive coatings, outdoor furniture, and building materials.

Key Country Highlights:

- United States: The market is projected to reach USD 359.34 million by 2032, driven by rising awareness among consumers and manufacturers about the harmful effects of UV radiation and growing demand in automotive and packaging applications.

- China: Demand is propelled by large-scale industrialization, infrastructure development, and increasing UV stabilizer use in construction and plastics manufacturing.

- Germany: Market growth is supported by strong investment in high-performance polymers for automotive and industrial uses, coupled with regulatory focus on product longevity.

- Brazil: Rising urbanization and industrial growth are driving demand for UV stabilizers, especially in packaging and agriculture sectors.

- Saudi Arabia: Infrastructure investment and the rapid expansion of the adhesives & sealants and packaging industries—boosted by platforms like noon.com—are fueling regional market growth.

UV Stabilizers Market Trends

Rising Awareness among Consumers about the Benefits of UV Stabilizers and their Ability to Extend the Lifespan of Products to Fuel Product Demand

UV stabilizers can extend the lifespan of products exposed to sunlight. These are the chemical compounds added to various materials to protect them from the harmful effects of UV radiation. They work by absorbing the UV energy and converting it into heat, which dissipates harmlessly into the surrounding environment. Stabilizers are particularly important in products that are exposed to sunlight for long periods, such as outdoor furniture, automotive parts, and building materials. Without stabilizers, the products would degrade and deteriorate much faster than they should, leading to premature failure and replacement.

In addition to extending the lifespan of products, the product can also help to maintain their appearance and performance over time. For example, outdoor furniture protected with UV materials will maintain its color and resist cracking, fading, and other forms of damage. Overall, the solutions are an important consideration for manufacturers and consumers. By protecting products from the detrimental effects of UV radiation, they can help extend their lifespan and reduce the need for replacement by saving both time and money in the long run. Asia Pacific witnessed a growth from USD 0.70 Billion in 2023 to USD 0.74 Billion in 2024.

Download Free sample to learn more about this report.

UV Stabilizers Market Growth Factors

Increasing Product Demand from Building & Construction Industry to Aid the Market Growth

There has been a steady increase in product demand from the building and construction industry. These stabilizers are essential in protecting building materials such as plastics, coatings, and polymers from the detrimental effects of UV radiation. The building and construction industry is constantly seeking innovative solutions to improve the durability and longevity of their products and UV stabilizers have proven to be an effective solution. With the increasing awareness of the harmful effects of UV radiation, these factors are expected to augment the UV stabilizers market share in the coming years.

Growing Product Utilization in Medical Industry to Propel Market Growth

In recent years, the use of UV stabilizers in the medical industry has increased significantly due to their effectiveness in safeguarding medical devices and equipment from the harmful effects of UV radiation. Medical devices, such as catheters, tubing, implants, and other components are often made of polymers that are susceptible to degradation and discoloration when exposed to UV light. This can lead to the weakening of the devices and compromise their safety and efficacy. UV stabilizers offer a solution to this problem by absorbing or reflecting UV radiation, thereby increasing the lifespan and durability of the medical equipment.

Moreover, the use of stabilizers in the medical industry has become increasingly important as the demand for high-quality medical devices continues to grow. With advancements in technology and the increasing complexity of medical devices, there is a need for innovative solutions that can enhance the performance and longevity of medical equipment. UV stabilizers have proven to be a reliable and effective solution in this regard. Furthermore, these stabilizers not only protect medical devices from UV radiation, but also offer other benefits, such as improved heat resistance, reduced discoloration, and enhanced mechanical properties. These properties are particularly useful in medical applications where the equipment is exposed to harsh environmental conditions, such as high temperatures and humidity.

RESTRAINING FACTORS

Environmental Concerns Surrounding UV Stabilizers Pose Challenges for Market Growth

UV stabilizers can accumulate in the soil, water, and air, potentially harming plants, animals, and humans. They also resist degradation and can persist in the environment for long periods. This can lead to bioaccumulation, where the chemical concentrations increase as they move up the food chain, potentially harming ecosystems. In addition, some products are toxic to aquatic life, further highlighting the potential negative impact of their use on the sustainable environment, which may hinder the growth of the market in recent times. It is important to carefully consider the use of stabilizers and explore alternative options that may be more environmentally friendly.

UV Stabilizers Market Segmentation Analysis

By Type Analysis

Hindered Amine Light Stabilizers (HALS) Segment Holds a Dominant Share in the Global Market Due to its Higher UV Stabilization Efficiency

Based on type, the market is categorized into Hindered Amine Light Stabilizers (HALS), UV absorbers, quenchers, and others.

The Hindered Amine Light Stabilizers (HALS) segment held a dominant market share of61.85% in 2026. The organic chemical compound serves as light stabilizers in polymers and coatings. HALS is a safeguarding agent against the detrimental effects of ultraviolet (UV) light on materials, thereby preventing fading, discoloration, and degradation. Moreover, HALS exhibits high efficacy at low concentrations and is not known to induce untoward effects on human health or the environment. This is extensively applied in various applications, including coatings for automotive and aerospace components, outdoor furniture, and building materials, thus providing impetus to the growth of the market significantly over the coming years.

By End-Use Industry Analysis

To know how our report can help streamline your business, Speak to Analyst

Packaging Segment to Hold Major Share Owing to the Growing Demand from Light Sensitive Product Category

By end-use industry, the market is segmented into packaging, automotive, agriculture, building & construction, adhesives & sealants, and others.

Packaging is the major leading segment in the UV stabilizers industry contributing 49.71% globally in 2026, as they are becoming increasingly popular in food packaging. Stabilizers can help protect the food from harmful UV rays, which can cause degradation of nutrients and spoilage. Blocking out these harmful rays can help keep food fresher for longer and prevent the growth of harmful bacteria and other microorganisms, which can further prolong the shelf life of food. With the increasing demand for sustainable packaging solutions, UV stabilizers are essential in producing high-quality packaging materials that can withstand exposure to UV radiation. This trend is expected to continue in the coming years as consumers become more environmentally conscious and demand for eco-friendly packaging options tends to rise. Companies specializing in these stabilizers for packaging applications will likely see significant growth and profitability shortly.

- The automotive segment is expected to hold a 21.5% share in 2024.

Automotive components perform substantial growth due to being constantly exposed to harsh environmental conditions such as heat, sunlight, and moisture. It is essential for the materials used to withstand these elements and maintain high performance throughout their service life. In North America, the Society of Automotive Engineers (SAE) has set industry standards for interior and exterior automotive components, dictating performance requirements in end-use environments. To meet these stringent requirements, advanced polymer additives such as UV light stabilizers are added to plastic-based materials, which helps to extend the service life of automotive components that boosts the market in coming years.

REGIONAL INSIGHTS

Geographically the market is studied across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Asia Pacific UV Stabilizers Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific

Asia Pacific is estimated to hold the largest market size of USD 0.78 billion in 2025. owing to widespread product usage in the industrial and commercial sectors. The market is being driven by the growth of end-use industries such as packaging, automotive, and construction. The increasing demand for the material in China, India, and Japan is expected to drive the growth of the market in the region. The Japan market is valued at USD 0.14 billion by 2026, the China market is valued at USD 0.36 billion by 2026, and the India market is valued at USD 0.15 billion by 2026.

To know how our report can help streamline your business, Speak to Analyst

North America

North America is likely to rise considerably during the forecast period. UV stabilizers are becoming increasingly popular in the North American market as more consumers turn to these products to protect their valuable investments. With the right material, consumers ensure their products look great for years, even in harsh outdoor conditions. The product is largely available for cars, boats, and furniture, with plenty of options in the region. The U.S. market is valued at USD 0.26 billion by 2026.

Europe

Europe has witnessed significant industrial development in the last decade. The increasing investment of the European Union in automobile and construction industries is the main factor driving the global market growth. The market is expected to witness significant growth in Germany, France, and the U.K. The UK market is valued at USD 0.07 billion by 2026, while the Germany market is valued at USD 0.14 billion by 2026.

The demand for stabilizers is rising in Latin America, particularly in industries such as packaging, adhesives, and agriculture. The rapid urbanization and growing number of industries, along with the lower labor cost in the region, also foster product demand during the forecast period.

Middle East and Africa

The Middle East and Africa is expected to exhibit significant market growth over the study period. This is due to increased investment in the development of infrastructure and rapid growth in adhesives & sealants industry in Saudi Arabia. For instance, the emergence of e-commerce platforms such as noon.com is boosting the growth of the packaging industry, increasing the usage of the product in the region.

List of Key Companies in UV Stabilizers Market

Leading Industry Players Forge Ahead with Expansion and Innovation

Prominent industry participants include BASF SE, Clariant AG, Solvay, Songwon, and other notable firms. These companies are actively engaged in expanding their production capacities, introducing new product lines, forming strategic alliances, pursuing acquisitions, and fostering partnerships to enhance their competitive position within the market.

BASF SE, for instance, boasts a significant presence in the European market, serving as the region's largest producer of specialized chemicals. The company operates across six distinct market segments, encompassing chemicals, materials, industrial solutions, surface technologies, nutrition & care, and agricultural solutions. Likewise, the remaining key market players have also established a robust regional footprint, well-developed distribution networks, and a diverse portfolio of products.

LIST OF KEY COMPANIES PROFILED:

- BASF SE (Germany)

- Clariant AG (Switzerland)

- Songwon (South Korea)

- Solvay (Belgium)

- Suqian Unitech Corp Ltd. (China)

- Everlight Chemical Industrial Corp (Taiwan)

- SABO S.p.A. (Italy)

- Lycus Ltd., LLC (U.S.)

- Sarex (India)

- Jiangsu Chemk Co.,Ltd. (CHEMK) (China)

KEY INDUSTRY DEVELOPMENTS:

- November 2022 – Songwon recently introduced two new products: the Songnox 9228 antioxidant and the Songsorb 1164 UV absorber. As claimed by the company, these polymer additives have proven to be ideal for various industries, such as packaging, agriculture, building, construction, and home and personal care applications. The company aims to provide products with unmatched quality, consistency, and reliability to their consistent customers.

- November 2022 – SABO S.p.A. announced its acquisition of the TAA and derivatives business from Evonik Industries AG, along with the production sites in Marl, Germany, and Liaoyang, China. This business is critical in providing the raw materials for manufacturing Hindered Amine Light Stabilizers (HALS). SABO's acquisition would ensure a continued supply of additives that are used in automotive components, agricultural films, building materials, and consumer goods.

- July 2022 – Solvay announced a new portfolio of UV-C stabilizers. The materials are designed to target hygiene applications. Under this product segment, bright (UV) light in the UV-C range (200 to 280 nm) is designated for polyolefin applications, including clinical hardware for working rooms, airplanes, and sports venues.

- July 2021 – UniteChem Group announced major investments in expanding its technical support capabilities for customers in Europe and worldwide. The company is committed to investing 5% of its total revenue in R&D and opened a second R&D and Innovation Center in Shanghai, equipped with state-of-the-art testing equipment. This move would enhance the company's technical support capabilities to conduct all major polymer accelerated weathering aging tests such as UV exposure, Xenon lamps, and heat oxygen, among others, and maintain its position as a leading supplier in the industry.

- January 2020 - Solvay expanded its project in Willow Island, West Virginia, by increasing the HMW (HALS) stabilizer capacity rate and intermediate production. This expansion would aim to meet Solvay's customers' needs and ensure their supply chain's security. Solvay is committed to growing with its customers and delivering innovative solutions.

REPORT COVERAGE

The report provides a detailed market analysis and focuses on crucial aspects such as leading companies, products, and applications. It also offers insights into market trends and highlights vital industry developments. This report includes historical data & forecasts revenue growth at the global, regional, and country levels, and analyzes the industry's latest market dynamics and opportunities. In addition to the abovementioned factors, the report encompasses various factors contributing to the market growth in recent years.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 5.50% from 2026 to 2034 |

|

Unit |

Value (USD Billion); Volume (Million Ton) |

|

Segmentation |

By Type

By End-Use Industry

By Geography

|

Frequently Asked Questions

According to Fortune Business Insights, the global UV stabilizers market was valued at USD 1.64 billion in 2025 and is projected to grow from USD 1.73 billion in 2026 to USD 2.8 billion by 2034, exhibiting a CAGR of 5.50% during the forecast period.

The UV stabilizers market is experiencing strong growth due to rising demand in industries like packaging, automotive, construction, and healthcare. The increasing awareness about UV-induced material degradation and the need for longer-lasting, UV-resistant products are key growth drivers.

Recording a CAGR of 5.50%, the market will exhibit steady growth over the forecast period of 2026-2034.

The packaging industry holds the largest share in the UV stabilizers market. These additives are widely used in food and pharmaceutical packaging to protect products from UV radiation, prolong shelf life, and maintain material integrity.

The main types of UV stabilizers include Hindered Amine Light Stabilizers (HALS), UV absorbers, quenchers, and others. Among these, HALS dominates the market due to its high stabilization efficiency and environmental compatibility.

The Asia Pacific region dominates the UV stabilizers market with a market share of 48% in 2025, led by industrial expansion and high demand from China, India, and Japan in sectors like packaging, automotive, and construction.

In the automotive sector, UV stabilizers are added to interior and exterior plastic components to protect them from fading, cracking, and degradation caused by sunlight exposure, helping vehicles maintain appearance and performance over time.

Yes, some UV stabilizers may pose environmental risks due to their persistence in soil and water, potential for bioaccumulation, and toxicity to aquatic life. As a result, there is growing interest in eco-friendly alternatives and sustainable additives.

Key players in the UV stabilizers market include BASF SE, Clariant AG, Solvay, Songwon, and SABO S.p.A. These companies are focusing on product innovation, strategic acquisitions, and capacity expansion to strengthen their global market presence.

Get 20% Free Customization

Expand Regional and Country Coverage, Segments Analysis, Company Profiles, Competitive Benchmarking, and End-user Insights.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us