Torque Sensor Market Size, Share & Industry Analysis, By Type (Rotary Torque Sensors and Reaction Torque Sensors), By Technology (Strain Gauge, Magnetoelastic, Surface Acoustic Wave, and Optical), By Industry (Industrial, Automotive, Test & Measurement, Aerospace & Defense, Healthcare, and Others), and Regional Forecast, 2026 – 2034

TORQUE SENSOR MARKET SIZE AND FUTURE OUTLOOK

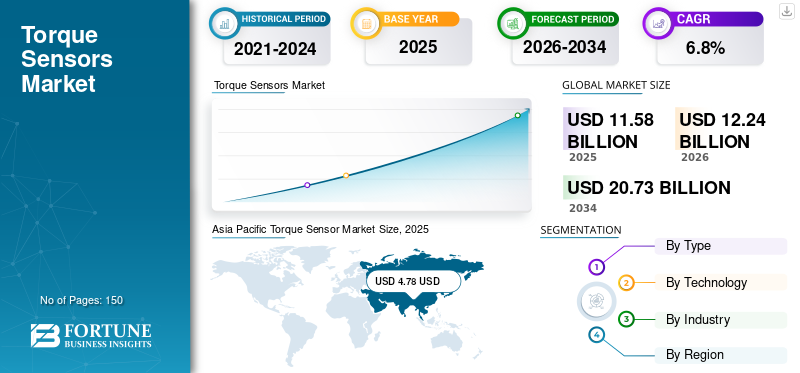

The global torque sensor market size was valued at USD 11.58 billion in 2025. The market is projected to grow from USD 12.24 billion in 2026 to USD 20.73 billion by 2034, exhibiting a CAGR of 6.8% during the forecast period. Asia Pacific dominated the global torque sensor market with a market share of 41.27% in 2025.

A torque sensor is a tool or device that you can use to measure the torque placed on a shaft or other mechanical parts. It provides an accurate readout of what happens to a part as it is used, so that users can monitor and control its performance. There are several areas where these sensors are becoming increasingly important, including automotive, manufacturing, and testing or measurement; therefore, the expansion of this market is driven by consumers' demand for greater accuracy, reliability, and longer-lasting technologies. Advanced technologies used in these sensors include strain gauges, magnetoelastic, and surface wave sensors.

Furthermore, several key industry players, such as HBK, Kistler Group, TE Connectivity, Vishay Precision Group, and Honeywell International Inc., operating in the market, are aiming on expanding product portfolios through mergers and acquisitions, technological innovation, forming strategic partnerships with automotive and industrial players, and enhancing global distribution networks to cater to growing demand in emerging markets.

IMPACT OF GENERATIVE AI

Growing Adoption of Generative AI is Enhancing the Performance and Efficiency of Sensors

Generative AI is increasingly reshaping the market by enabling smarter, more data‑driven design, predictive maintenance, and digital twin capabilities that help manufacturers reduce downtime and optimize sensor performance across automated systems. For example, the use of generative AI in conjunction with machine learning enhances the learning capabilities of torque sensors, improving their accuracy in collaborative robotics and other automated industrial applications.

In addition, AI‑enabled manufacturing tools are also accelerating product development cycles, allowing designers to simulate and refine sensor integration more rapidly, which can lead to better torque sensor robustness and adaptability.

- In January 2026, Bosch announced to invest over USD 2.9 billion in AI development by 2027. Through this investment, the company plans to shift toward AI‑augmented sensing and control systems.

TORQUE SENSOR MARKET TRENDS

Surge in Integration of Torque Sensors with IoT and AI Technologies is Fueling Market Growth

The growing adoption of torque sensor technology with AI and IoT (Internet of Things) is causing a sea change in how many businesses operate from the standpoint of collecting data and performing predictive analysis on that data in real time. These sensors are connected to an IoT network, providing operators with continuous access to torque data from multiple sources, such as machines, motors, and electrical panels, enabling them to gain visibility into their entire production process. These types of sensors help operators identify both inefficiencies within their operations as well as potential failures before those failures actually happen, which ultimately results in less unplanned downtime. AI enhances the ability of manufacturers to use sensor data effectively for maintenance forecasting, performance optimization, and automated adjustments in industrial applications by applying sophisticated algorithms to vast quantities of sensor data.

This trend is particularly significant in industries such as automotive and manufacturing, where precision and reliability are critical to operational efficiency. Additionally, it supports the transition towards Industry 4.0, where automation and smart manufacturing play a central role in driving productivity and reducing costs.

Download Free sample to learn more about this report.

MARKET DYNAMICS

MARKET DRIVERS

Increasing Adoption of Automation and Robotics Across Industries Aids Market Growth

The use of automation and robotics continues to increase across all industry sectors, driven by the need for torque sensors to provide accurate feedback for motion control, assembly, and quality control in manufacturing and other industrial operations. For instance,

- In December 2025, global factory installations of industrial robots reached 542,076 units, up from 2024, more than double the number installed approximately a decade ago, demonstrating continued growth in the use of automation in manufacturing/logistics.

As industries continue to develop automated processes to increase efficiency and fill the gap left by an aging workforce, the need for sensors, such as torque sensors, to provide accurate force measurement/control in robot joint/actuator applications is expected to grow. This factor is expected to drive the torque sensor market growth during the forecast period.

MARKET RESTRAINTS

High Cost of Advanced Sensors May Hinder Market Growth

Advanced sensors are significantly constrained in the torque sensor industry, as they are generally cost-prohibitive compared to traditional strain gauge based torque sensors. The costs associated with the development of non-contact torque sensors (magnetoelastic and surface acoustic wave) stem from their use of advanced materials, advanced manufacturing techniques, and more sophisticated designs to manufacture high-performance sensors. Due to this increased cost, industries with limited budgets or those seeking to keep operating expenses to a minimum are less likely to purchase and use these types of sensors. This creates a limitation on the widespread adoption of advanced torque sensors in industries where equipment costs are a major consideration, particularly in highly competitive environments.

Additionally, the cost factor will continue to be a limiting factor in developing new technology in developing countries, since the development of new technology will always be closely related to its cost.

MARKET OPPORTUNITIES

Rapid Expansion of Electric Vehicles (EVs) to Create New Opportunities for Market Growth

The growth in Electric Vehicle (EV) sales creates a significant opportunity for the market, as both EV powertrains and electric steering systems must accurately measure torque to ensure safety, efficiency, and control. With the increase in EV adoption, more vehicles will feature turning sensors for Electric Power Steering (EPS), battery-efficient motor control, and regenerative braking systems, increasing the overall addressable market for sensors beyond traditional Internal Combustion Engine (ICE) applications. For instance,

- In January 2025, according to data published by the International Energy Agency (IEA), global EV sales reached approximately 12 million units in 2024, a substantial increase from around 6.6 million in 2021, indicating sustained demand growth that drives sensor requirements.

As automotive manufacturers continue to add EVs to their product line and implement advanced driver-assist systems, the torque sensor will become increasingly essential to ensuring performance and safety. Therefore, the growth of EVs represents a key opportunity for the sensor manufacturing industry.

Segmentation Analysis

By Type

Expansion of Automotive and Industrial Automation Boosts Rotary Torque Sensors Segment Growth

Based on type, the market is divided into rotary torque sensors and reaction torque sensors.

Rotary torque sensors segment dominated the global market in 2025 and is expected to grow at the highest CAGR of 8.0% over the forecast period. The use of rotary sensors continues to expand within the EPS system and other automotive and industrial applications related to testing, control, and monitoring of motors and shafts. The ability of these sensors to accurately measure dynamic torque at all times makes them essential for providing real-time feedback to optimize performance and safety in many applications.

Reaction torque sensors are expected to grow at a moderate CAGR of 4.2% during the forecast period, owing to continued use in applications such as calibration, torque measurement in non-rotating systems, and quality control in industrial settings, where high precision is essential, and demand for advanced features remains stable.

By Technology

Rising Demand for Reliable and Cost-Effective Sensors Drives Strain Gauge Segment Growth

Based on technology, the market is categorized into strain gauge, magnetoelastic, surface acoustic wave, and optical.

In 2025, the strain gauge segment accounted for the largest market share. This growth is driven by its proven accuracy, reliability, and cost-effectiveness in a wide range of applications, including automotive, industrial automation, and testing. Strain gauges have become a preferred method for precision measurements in many industries, as they are already established in the marketplace and can be easily integrated into existing systems.

Magnetoelastic segment is expected to grow at the highest CAGR of 8.5% during the forecast period. This growth is driven by its non-contact measurement capabilities, durability in harsh environments, and increasing demand for advanced, reliable sensing solutions in automotive and industrial applications.

To know how our report can help streamline your business, Speak to Analyst

By Industry

Growth of Electric Vehicles and Advanced Manufacturing Boost Automotive Sector’s Dominance

Based on industry, the market is classified into industrial, automotive, test & measurement, aerospace & defense, healthcare, and others (energy & utilities, among others).

Automotive segment held a dominant market share in 2025 and is expected to grow at the highest CAGR of 8.3% during the forecast period. This is owing to the increasing use of Electric Vehicles (EVs) and the growing need for Advanced Driver Assistance Systems (ADAS), which require accurate torque measurement for both Electric Power Steering (EPS) and motor control, thereby increasing the need for torque sensor accuracy. Furthermore, with this increased focus on efficiency and automation, reducing waste, and increasing the productivity of manufacturing processes within this sector, there will be an even greater need for reliable sensors to meet the required performance and safety standards.

Aerospace & defense is expected to grow at a moderate CAGR of 7.3% over the forecast period. This is owing to the ongoing need for high-precision torque sensors in mission-critical applications, such as aircraft testing, satellite systems, and defense machinery, where reliability and accuracy are paramount.

Torque Sensor Market Regional Outlook

By geography, the market is categorized into North America, South America, Europe, the Middle East & Africa, and Asia Pacific.

Asia Pacific

Asia Pacific Torque Sensor Market Size, 2025 (USD Billion)

To get more information on the regional analysis of this market, Download Free sample

Asia Pacific held the largest torque sensor market share in 2024, valued at USD 4.50 billion, and also maintained the leading share in 2025, with USD 4.78 billion. The market in Asia Pacific is expected to increase, owing to the rapid industrialization, high demand for automation, and the growing automotive and Electric Vehicle (EV) sectors in countries such as China, Japan, and India. Additionally, the increased use of advanced technology and high adoptions of robots also contribute to the dominating position of Asia Pacific in the market. In the region, India and China are estimated to reach USD 0.64 billion and USD 1.19 billion, respectively, in 2026. For instance,

- In February 2025, according to an industry expert’s analysis, ASEAN‑6 electric vehicle adoption accelerated from about 9 % in 2023 to 13 % in 2024, boosted by government incentives and increasing eco‑awareness across Southeast Asian markets.

These factors play a significant role in fueling the market growth.

China Torque Sensor Market

China’s torque sensor market is projected to be one of the largest worldwide, with 2026 revenues estimated at around USD 1.19 billion, representing roughly 9.7% of global torque sensor sales.

To know how our report can help streamline your business, Speak to Analyst

Japan Torque Sensor Market

The Japan torque sensor market in 2026 is estimated at around USD 0.97 billion, accounting for roughly 7.9% of global torque sensor revenues. This is due to the country's strong focus on technological innovation, particularly in the automotive and robotics sectors, where the demand for precise torque sensors in electric vehicles, autonomous driving systems, and industrial automation is rapidly increasing.

India Torque Sensor Market

The India torque sensor market in 2026 is estimated at around USD 0.64 billion, accounting for roughly 5.2% of global torque sensor revenues.

North America

North America is estimated to reach USD 2.85 billion in 2026 and secure the position of the second-largest region in the market. In the region, demand for advanced automotive technologies, including Electric Vehicles (EVs) and autonomous driving systems, has spurred growth by creating a need for precision torque sensors for motor controls and safety applications. The North American market is also benefiting from a high level of focus on industrial automation, robotics, and the Internet of Things (IoT), resulting in a significant increase in the requirement for accurate torque measurement solutions across many industries including aerospace, energy and utility, and the manufacturing industry.

U.S. Torque Sensor Market

Based on North America’s significant contribution and the U.S. dominance within the region, the U.S. market can be analytically approximated at around USD 2.28 billion in 2026, accounting for roughly 18.6% of global torque sensor sales.

Europe

Europe is anticipated to record a growth rate of 6.0% in the coming years, which is the third largest among all regions, and reach a valuation of USD 3.34 billion by 2026. The market is observing significant growth in the region, driven by the increasing adoption of Electric Vehicles (EVs) and stringent regulations promoting vehicle electrification and carbon emission reduction, which require advanced torque sensing technologies for motor control and energy efficiency. Additionally, Europe’s strong focus on Industry 4.0, with significant investments in automation, robotics, and smart manufacturing, is fueling the demand for precise torque sensors across various industrial applications.

U.K Torque Sensor Market

The U.K. torque sensor market in 2026 is estimated at around USD 0.62 billion, representing roughly 5.1% of global torque sensor revenues.

Germany Torque Sensor Market

Germany’s torque sensor market is estimated to reach around USD 0.66 billion in 2026, equivalent to around 5.4% of global torque sensor sales.

South America

South America is expected to witness moderate growth in this market during the forecast period. The South America market is set to reach a valuation of USD 0.54 billion in 2026. This is owing to the increasing industrial automation and infrastructure development in key sectors such as manufacturing, mining, and automotive, which require accurate torque measurement for machinery, motor control, and process optimization.

Middle East & Africa

The Middle East & Africa is estimated to reach USD 0.40 billion in 2026 and is expected to grow rapidly in the coming years. This is owing to the region's expanding industry and the technologies it supports. In particular, industrialization in the MEA includes the growing need for accurate torque measurement for the optimization of machinery and equipment in various sectors, such as oil and gas, energy, and manufacturing. Industrialization, coupled with an increased focus on infrastructure development, automated production in key industries, and rising investment in renewable energy and smart technologies, continues to propel the demand for torque sensors across the Middle East & Africa region. In this region, the GCC is likely to reach a value of USD 0.13 billion in 2026.

COMPETITIVE LANDSCAPE

Key Industry Players

Focus on Expanding Product Portfolio by Key Players to Fuel Market Advancement

The global torque sensor market holds a semi-consolidated market structure, with prominent players such as HBK, Kistler Group, TE Connectivity, Vishay Precision Group, and Honeywell International holding significant positions. The leadership of these companies is supported by ongoing strategic initiatives, including the expansion of automotive-grade and industrial sensor portfolios, the development of non-contact and high-precision sensing technologies, and the integration of these sensors with digital signal conditioning, embedded electronics, and software platforms. Market participants are also focusing on collaborations with automotive OEMs, robotics manufacturers, and industrial equipment providers, which are helping players align product development with evolving application requirements and safety standards. For instance,

- In November 2024, Kistler showcased its KiTorq 4552A torque flange and highlighted flexible, space-saving torque measurement solutions for high-speed electric motor testing, reinforcing the trend toward compact, integrated systems for modern electrified drivetrains.

Other prominent players in the market include Futek Advanced Sensor Technology, Althen Sensors & Controls, Lorenz Messtechnik GmbH, Sensor Technology Ltd, and Nidec Corporation. These companies are likely to focus on new product launches, miniaturization of torque sensors, improved performance in harsh operating conditions, and long-term calibration stability to strengthen their competitive positioning. Continued investments in research and development, along with geographic expansion and customization for end-use applications, are anticipated to support market growth and help manufacturers capture emerging opportunities during the forecast period.

LIST OF KEY TORQUE SENSOR COMPANIES PROFILED

- HBK (Germany)

- Kistler Group (Switzerland)

- TE Connectivity (Switzerland)

- Vishay Precision Group (U.S.)

- Honeywell International (U.S.)

- Futek Advanced Sensor Technology (U.S.)

- Althen Sensors & Controls (Netherlands)

- Lorenz Messtechnik GmbH (Germany)

- Sensor Technology Ltd (U.K.)

- Nidec Corporation (Japan)

KEY INDUSTRY DEVELOPMENTS

- December 2025: Sensor Technology introduced the SGR523 digital rotary torque sensor with an integrated angle encoder, designed for torque-angle monitoring in manufacturing and process control.

- June 2025: Honeywell International highlighted its strategic focus on AI, autonomy, and digital transformation at the 2025 Honeywell Users Group in San Antonio, U.S. This strategy reflects the company’s broader investments in advanced automation and sensing technologies that support torque sensor integration in industrial systems.

- March 2025: Sensor Technology announced the launch of SGR525/526 square-drive torque sensors aimed at fastening, industrial, and lab applications, strengthening its rotary torque sensor lineup.

- February 2025: Vishay Precision Group introduced a high‑precision inductive position sensor (RAIK060), underscoring the company’s broader sensor technology innovations that can complement torque sensing applications in industrial environments.

- September 2024: TE Connectivity completed the acquisition of Sense Eletronica Ltda in Brazil. Through this acquisition, the company aims to strengthen its position in industrial sensors and automation.

- July 2024: Kistler Group launched RoaDyn P109 Wheel Torque Transducer (WTT) for vehicles weighing up to 3.5 tons. Through this offering, the company aims to strengthen its portfolio related to automotive industry.

- June 2024: HBK launched its next‑generation T110/T100 torque sensor with integrated telemetry at the 2024 Automotive Testing Expo in Stuttgart, Germany, showcasing advanced torque measurement for powertrain testing and electric vehicle applications.

REPORT COVERAGE

Request for Customization to gain extensive market insights.

Report Scope & Segmentation

|

ATTRIBUTE |

DETAILS |

|

Study Period |

2021-2034 |

|

Base Year |

2025 |

|

Estimated Year |

2026 |

|

Forecast Period |

2026-2034 |

|

Historical Period |

2021-2024 |

|

Growth Rate |

CAGR of 6.8% from 2026-2034 |

|

Unit |

Value (USD Billion) |

|

Segmentation |

By Type, Technology, Industry, and Region |

|

By Type |

· Rotary Torque Sensors · Reaction Torque Sensors |

|

By Technology |

· Strain Gauge · Magnetoelastic · Surface Acoustic Wave · Optical |

|

By Industry |

· Industrial · Automotive · Test & Measurement · Aerospace & Defense · Healthcare · Others (Energy & Utilities, among others.) |

|

By Region |

· North America (By Type, Technology, Industry, and Country) o U.S. (By Technology) o Canada (By Technology) o Mexico (By Technology) · South America (By Type, Technology, Industry, and Country) o Brazil (By Technology) o Argentina (By Technology) o Rest of South America · Europe (By Type, Technology, Industry, and Country) o U.K. (By Technology) o Germany (By Technology) o France (By Technology) o Italy (By Technology) o Spain (By Technology) o Russia (By Technology) o Benelux (By Technology) o Nordics (By Technology) o Rest of Europe · Middle East & Africa (By Type, Technology, Industry, and Country) o Turkey (By Technology) o Israel (By Technology) o GCC (By Technology) o North Africa (By Technology) o South Africa (By Technology) o Rest of the Middle East & Africa · Asia Pacific (By Type, Technology, Industry, and Country) o China (By Technology) o India (By Technology) o Japan (By Technology) o South Korea (By Technology) o ASEAN (By Technology) o Oceania (By Technology) o Rest of Asia Pacific |

Frequently Asked Questions

According to Fortune Business Insights, the global market value stood at USD 11.58 billion in 2025 and is projected to reach USD 20.73 billion by 2034.

In 2025, the Asia Pacific market value stood at USD 5.12 billion.

The market is expected to exhibit a CAGR of 6.8% during the forecast period of 2026-2034.

By type, the rotary torque sensors segment dominated the market in 2025.

Increasing adoption of automation and robotics across industries are the key factors driving the market.

HBK, Kistler Group, TE Connectivity, Vishay Precision Group, and Honeywell International are the major players in the global market.

Asia Pacific dominated the market in 2025 with the largest share.

Get 20% Free Customization

Expand Regional and Country Coverage, Segments Analysis, Company Profiles, Competitive Benchmarking, and End-user Insights.

Related Reports

-

US +1 833 909 2966 ( Toll Free )

-

Get In Touch With Us